.jpg)

_0rfh.jpg)

LY Vertical Lube Oil Pump

Gas & Steam Turbine Lube Oil Pump

Gas & Steam Turbine Lube Oil Pump

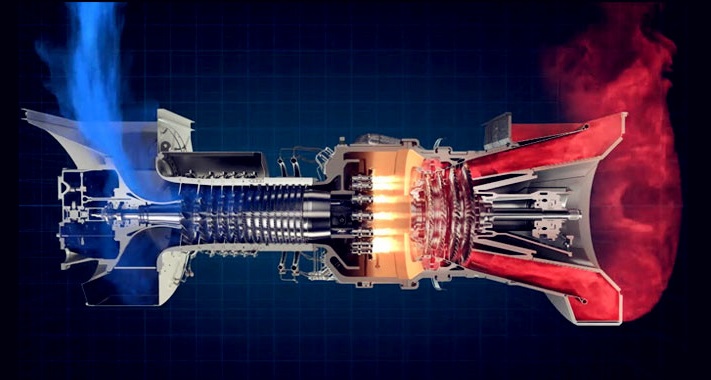

The gas turbine lubrication system is a critical component of gas

turbines in the power generation and aviation industries. It ensures the

smooth operation of these machines by providing lubrication, cooling,

and protection against wear and tear.

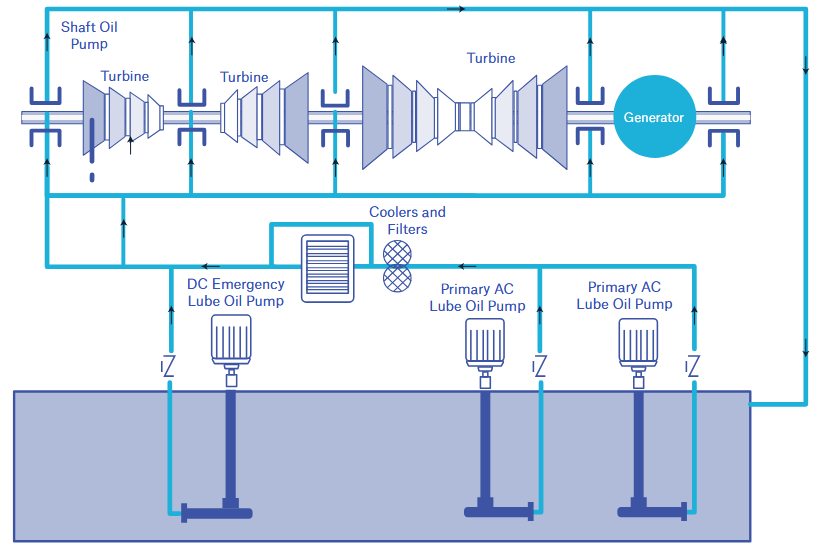

Gas Turbine Lubrication System, is the heart of any gas turbine. This part functions by providing essential lubrication, cooling, and cleaning to critical components. It starts with an oil reservoir, pumps circulate oil, filters remove contaminants, and heat exchangers cool the oil. Valves and control mechanisms regulate oil flow, while monitoring systems ensure optimal operation. Regular maintenance is key to its performance and longevity.

In the realm of gas turbines, comprehending the main components of the lubrication system is pivotal. Let’s delve into these critical elements that ensure the smooth operation of these powerful machines.

1-Main Oil Pump

The main oil pump serves as the lifeblood of the system. Its primary responsibility is to circulate the primary turbine oil throughout the system, delivering vital lubrication to essential components. This continuous oil flow is crucial for minimizing friction and wear, allowing the turbine to operate efficiently and reliably.

2-Auxiliary Oil Pump

Auxiliary oil pumps has an important duty in enhancing the reliability of the lubrication system. These pumps serve as backups or additional pumps to ensure continuous oil circulation. In the event of a primary pump failure, auxiliary pumps step in, preventing oil starvation and safeguarding the turbine’s health.

3-Emergency Oil Pump

Emergency oil pumps are the last line of defense in critical situations. These pumps are designed to activate under extreme and hard conditions, ensuring lubrication and cooling system, even when all else fails. Their robustness and reliability are paramount for preventing catastrophic turbine failures.

LY series vertical lubricating oil pump is a single-stage or multi-stage centrifugal pump. It is suitable for lubrication systems of 15 to 1000MW steam turbine generator sets, gas turbine generator sets and power steam turbines, etc., for delivering turbine oil at normal temperature. It can be used as high-pressure start-up oil pumps, AC lubricating oil pumps, DC emergency oil pumps, etc.

Performance range: Flow rate 12 - 200 m³/h, Head 16 - 245 m.

Temperature range: +20℃ to +60℃

Structural features:  LY series are single-stage or multi-stage vertical submersible centrifugal oil pumps.

LY series are single-stage or multi-stage vertical submersible centrifugal oil pumps.  The impeller is submerged in oil, making it easy to start.

The impeller is submerged in oil, making it easy to start.  Single-stage pumps are of volute type and guide vane type, and two-stage or multi-stage pumps are of guide vane type.

Single-stage pumps are of volute type and guide vane type, and two-stage or multi-stage pumps are of guide vane type.  The pump's inlet is located at the bottom of the pump and is axially suctioned. The pump's outlet is divided into upper and lower discharge ports, and can be single or multiple discharge ports.

The pump's inlet is located at the bottom of the pump and is axially suctioned. The pump's outlet is divided into upper and lower discharge ports, and can be single or multiple discharge ports.  The rotating part of the pump is supported and positioned at the top end by a rolling bearing, and is assisted by a sliding bearing at the bottom.

The rotating part of the pump is supported and positioned at the top end by a rolling bearing, and is assisted by a sliding bearing at the bottom.  The pump is connected to the prime mover by means of an internal gear type elastic coupling or a diaphragm coupling.

The pump is connected to the prime mover by means of an internal gear type elastic coupling or a diaphragm coupling.  The connection dimensions between the pump and the oil tank, the installation height, the position of the pump outlet, etc. can be determined or modified according to the customer's requirements.

The connection dimensions between the pump and the oil tank, the installation height, the position of the pump outlet, etc. can be determined or modified according to the customer's requirements.

FSM INDUSTRIAL CO.,LTD

No.898, Xincheng St., Muping, Shandong

P.R China

Phone: +86-535-2102728

Email: Sales@fsmindustrial.com

Contact

Company